Bryan Windmill Tail Vane Restoration

The tail vane was in reasonable shape but a little bent, however, that could be straightened as there really isn't much to this part except probably the one crucial part that connects it to the gearbox. This was pretty well worn and must of had a lot of use to cause this much wear. Again I got I good tip or idea from Bryan Windmills in Colac on a good way to restore the tail vane with as little impact to the original as possible.

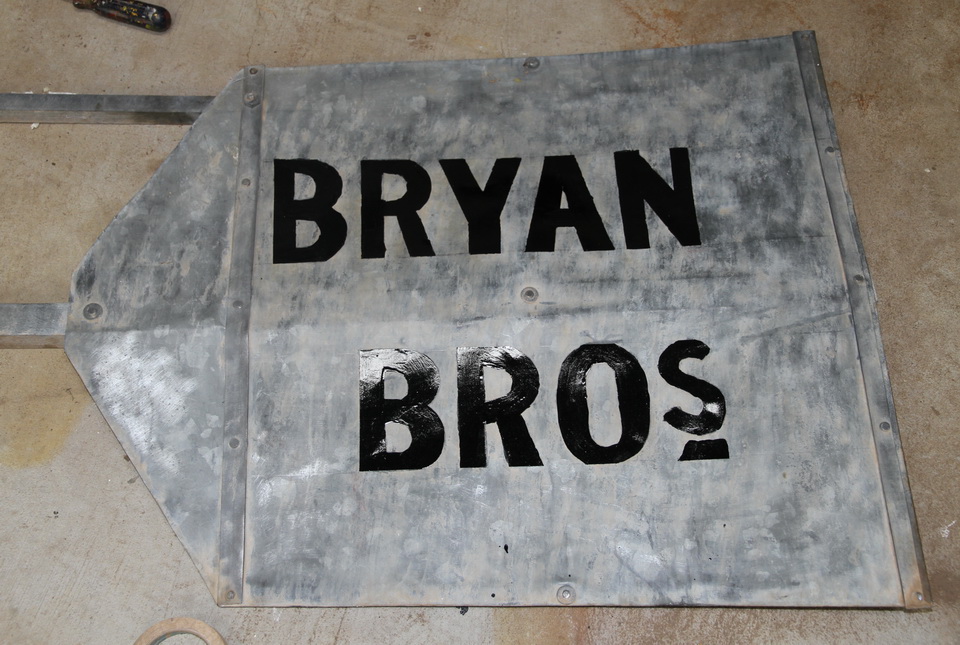

What I also found amazing was although the paint was well faded or gone I could easily see the scratch marks in the Galvanised sheeting that the original sign writer had use to lay out his script.

Not being a great free hand artist I used these original lines as tape lines I then taped out as much of the rest of the lettering I could and then gave it a new coat of paint.

It looks a bit rough with the tape still on, but that's the idea of the tape it allows you to go over the lines with a good thickness of paint. The finished product probably is just about as good as new. The quality of paint at least should be.

The part that had worn on the tail vane of course was where it attaches to the Gearbox or windmill engine as they are sometimes called. This part is made of mild steel with a good length of the steel bent in half then riveted to the angle steel, and the end part drilled to fit on the axle. As you can see in the picture below this was pretty badly worn. so I cut off this small section, and out of two 6mm pieces welded together made a new piece and welded it back on to the old part of the steel where I had cut it off.

There is some adjustment on the attachment piece to gearbox to adjust the length which then adjusts the height of the vane when in the working position. Which was good as you can see working out the exact position of the original hole relative to everything else was a bit of a guess. Then the hole also had to be tight enough fitting not to slop around and cause more wear but also have the correct angle to allow the tale vane to rise in an upward motion as it furled. This was a bit more of a challenge than I originally thought.